Contact

· MTF Testing

Optical transfer function is recognized as a relatively objective and effective method for evaluating the imaging quality of optical systems.

The MTF measuring instrument is an instrument used to determine the optical transfer function (OTF) of the imaging system, used to check the imaging quality of the production lens and externally paid measurement.

It can measure the lens MTF value, distortion, focal length, chromatic aberration, chief ray angle, etc. MTF measurement accuracy is ±0.03MTF. Effective focal length accuracy ±0.05%-0.5%; distortion accuracy 0.1%-0.5%; astigmatism accuracy 0.1%-0.5%; chromatic aberration accuracy 0.5-5μm.

Measurable white light:

Wavelength 400-700nm, maximum spatial frequency 500lp/mm,

Can measure short wave, medium wave, long wave infrared:

Wavelength: short wave: 1300μm/1535μm; medium wave: 3-5μm; long wave: 8-12μm.

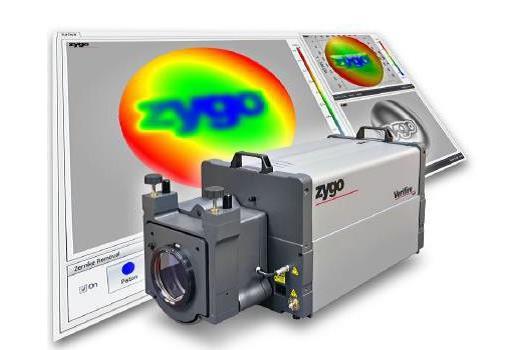

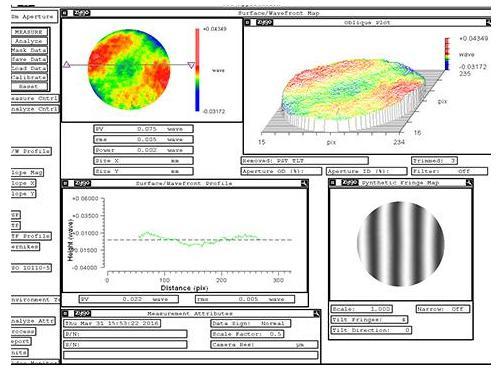

· Zygo interferometer measurement

Interferometry is the most scientific inspection method for optical parts. The wavefront distortion caused by the lens can be understood based on the interference pattern, so as to evaluate the wave aberration of the lens. A 6-inch zygo interferometer is used to measure the curvature and surface shape of a single optical element, and to measure the transmitted wavefront of the lens. The standard lens adopts zygo's F0.8, F1.1, F3.5, F7.2, and two flat mirrors, with a surface accuracy of 1/20λ

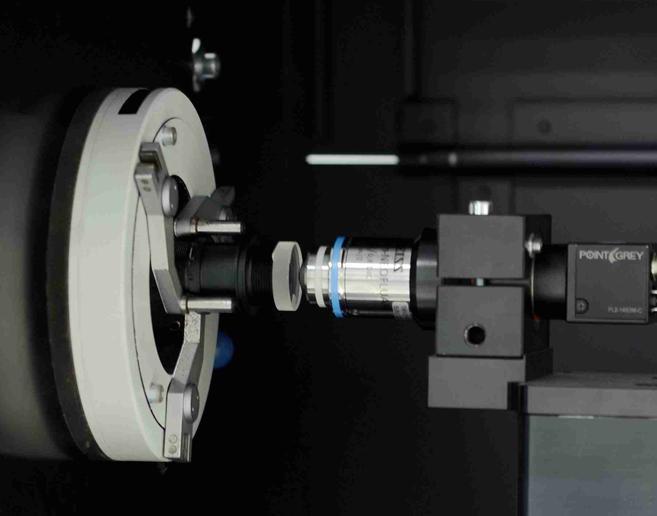

· Eccentricity detector

The eccentric tilt of the optical parts has a great influence on the imaging quality of the assembled finished lens, and the objective lens of different specifications can be replaced to measure different lenses. Measuring the eccentricity of the lens can be expressed in minutes or micrometers, and the focal length of the lens can be measured at the same time. The measurement of eccentricity can be divided into transmission eccentricity and reflection eccentricity.

· Spectrophotometer

In the lens, the coating on the surface of the lens is very important. The spectrophotometer can test the coating indicators on the surface of the optical parts and generate the coating curve, which can be divided into projection coating curve and reflective coating curve, which intuitively reflects whether the coating on the lens surface meets the requirements .

· Torch Block

The torch holder can be used to determine the approximate resolution of the assembled lens, as well as to measure the focal length of the lens, the back intercept, and the size of the entrance pupil and exit pupil.